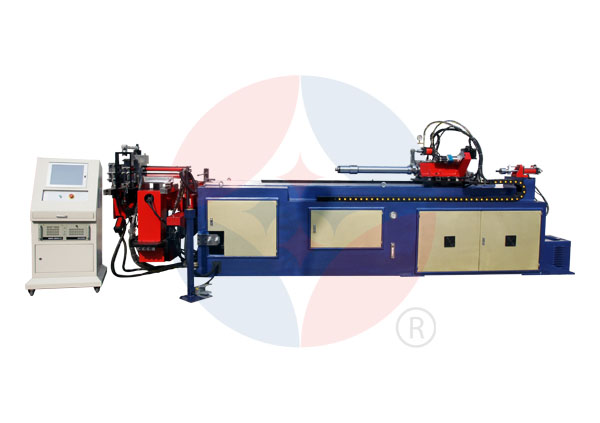

CNC Pipe Bending Machine

SB-50CNC-5A-3ST

SB-50CNC-5A-3ST Full-Automatic Three Dimensional Pipe Bending Machine

Fill in your information so that we can provide more detailed product information

Standard

--Industrial Computer offers easy access to auto and manual operating modes.

--System diagnostics and multiple language capability.

--Left and Right bending direction.

--Fully hydraulic clamping on clamp die and pressure die.

--Direct acting hydraulic pressure die with adjustable speed valve.

--Maximum 10000 sets of program storage,20 or more bends for each program.

--With Independent programmable speeds Y, B, and C axes.

--Programmable material spring back settings for each bend angle.

--Automatic mandrel/machine lubrication.

--Automatic release of tube prior to final bend.

--Bending Axis-Driven by Servo Motor,Feeding Axis-Driven by Servo Motor,Rotating Axis-Driven by Servo Motor,Left to Right Axis-Driven by Servo Motor,Up to Down Axis-Driven by Servo Motor.

--Obtain quality repeatable bends in steel, stainless, aluminum, titanium and brass.

--Foot Pedal Cycle start.

--With Air Cooling System.

--One set of Tooling for Draw Bending.

--Wiper die Bracket.

--Operation and Maintenance Manual.

--Tool Box with Adjusted Tools.

--Electric: As required (3 phase 220V or 380V or 415V...)

Optional

--Anticipate Mandrel Extraction.

--Machine effective length over mandrel.

--Safety Mat.

--Industrial Computer offers easy access to auto and manual operating modes.

--System diagnostics and multiple language capability.

--Left and Right bending direction.

--Fully hydraulic clamping on clamp die and pressure die.

--Direct acting hydraulic pressure die with adjustable speed valve.

--Maximum 10000 sets of program storage,20 or more bends for each program.

--With Independent programmable speeds Y, B, and C axes.

--Programmable material spring back settings for each bend angle.

--Automatic mandrel/machine lubrication.

--Automatic release of tube prior to final bend.

--Bending Axis-Driven by Servo Motor,Feeding Axis-Driven by Servo Motor,Rotating Axis-Driven by Servo Motor,Left to Right Axis-Driven by Servo Motor,Up to Down Axis-Driven by Servo Motor.

--Obtain quality repeatable bends in steel, stainless, aluminum, titanium and brass.

--Foot Pedal Cycle start.

--With Air Cooling System.

--One set of Tooling for Draw Bending.

--Wiper die Bracket.

--Operation and Maintenance Manual.

--Tool Box with Adjusted Tools.

--Electric: As required (3 phase 220V or 380V or 415V...)

Optional

--Anticipate Mandrel Extraction.

--Machine effective length over mandrel.

--Safety Mat.

| Name | Unit | Data | |

| Max Draw Bending Capacity Max Push Bending Capacity |

mm | ¢50*2 | |

| Max Bending Radius(Draw Bending) | mm | R250 | |

| Can customized as per customer’s requirement | |||

| Min Bending Radius(Draw Bending) | mm | R25 | |

| Draw Bending Radius Layer Difference | mm | 80 | |

| Rolling Radius Range | mm | 6D-∞ | |

| Punching Function | mm | As per customer’s detailed requirement | |

| Through Effective Distance Over Mandrel | mm | 3700 | |

| Can customized as per customer’s requirement | |||

| Max. One Time Feeding Length | mm | 2600 | |

| Can customized as per customer’s requirement | |||

| Max Bending Degree | ° | 190 | |

| Bending Unit | pieces | 32 | |

| Bending Axis | Speed | Deg/sec | 120 |

| Accuracy | ° | ±0.1 | |

| Power | KW | 7.5 Controlled by Servomotor | |

| Feeding Axis(Rolling) | Speed | mm/sec | 1000 |

| Accuracy | mm | ±0.1 | |

| Power | KW | 5 Controlled by Servomotor | |

| Rotating Axis | Speed | Deg/sec | 200 |

| Accuracy | ° | ±0.1 | |

| Power | KW | 0.75 Controlled by Servomotor | |

| Left-Right Axis | Accuracy | mm | ±0.1 |

| Power | KW | 0.75 Controlled by Servomotor | |

| Up-Down Axis | Accuracy | mm | ±0.1 |

| Power | KW | 1.5 Controlled by Servomotor | |

| Date Input | / | 1.Coordinate ( X, Y, Z ) | |

| / | 2.Working value ( Y, B, C ) | ||

| Max. Pressure | Mpa | 16 | |

| Max Storage Units | Group | 1000 | |

| Can be extended as per customer’s requirement | |||

| Machine Dimensions | mm | 4600*950*1450 | |

| Appro. Weight | Kgs | 4000 | |

SB-50CNC-5A-3ST

中文

中文 English

English